Guanajuato, at the forefront of R&D Centers

Guanajuato

By Lizete Hernández

The industry seeks to migrate to innovative production processes based on knowledge, which imply the strengthening or creation of research and innovation centers

Companies seek to invest in a Research and Development Center that is located within their facilities in order to create an atmosphere of empathy and belonging in their collaborators, as this encourages them to persevere and take their ideas to a tangible plane.

In the automotive industry, the range of action is wide, even more so when innovation is active for the development of new products and services, or their improvement.

In Guanajuato, only some companies in this sector have a Research and Development Center in their plants (Research and Development, R&D for short); However, the panorama begins to take a turn, since innovation has been at the forefront in recent years, since having R&D close to the productive activity of a company is crucial to extend the influences of the markets to through the commercialization of new products.

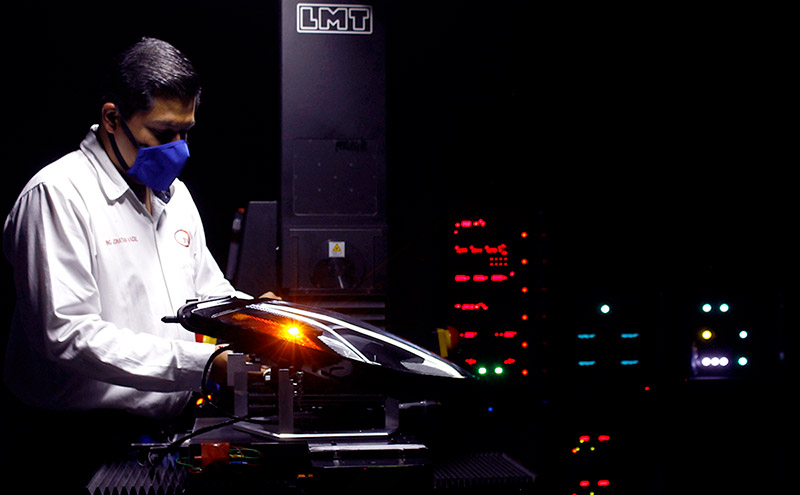

ZKW, SYNONYM OF WARRANTY AND INNOVATION

For Jan Seumenicht, vice president and general manager of ZKW México, an automotive company dedicated to the manufacture of headlights, lighting systems and electronics for premium brands, having an R&D in the plant means adding a competitive advantage to both the products and its personnel.

“With a center of this type, this closeness is created both with the production lines and with our clients and this offers the opportunity not only to speed up our responses but also to create multidisciplinary teams where we guarantee that all the knowledge, learning and lessons learned during start-up and serial development of our products they are immediately transferred to new projects ”, he explained.

He said that this encourages the personnel who work within the plant, because in coordination with this center, career plans can be created based on the ZKW ideology called "BRIGHT MINDS, BRIGHT LIGHTS", where those engineers whose passion is the design and development of aesthetically and visually important products such as vehicle headlights, have the opportunity to grow within the company.

Jan Seumenicht explained that the engineers who make up his R&D area have full responsibility for the design and development of products and processes.

He reported that the first laboratories were installed in 2014 and the departments are divided into design, light engineering, electronic engineering, prototypes, tooling, and metrology and quality laboratories.

Currently, more than 100 female and male engineers work in the different areas and have plans to double growth by the end of 2025.

For ZKW, the link with the academy is an important factor, therefore, they establish a link with the National Autonomous University of Mexico for laboratory tests and joint research. They also collaborate with the National Polytechnic Institute of Guanajuato Puerto Interior, which supports them in linking with engineering students for training and future hiring.

Among the projects that have been carried out within this R&D of ZKW, highlights the design and development of 100% Mexican headlights for clients such as Volvo and Navistar and, currently, they are developing projects for brands such as Ford and General Motors, in addition to having collaborated with BMW and Mercedes Benz.

“The level of commitment and the desire to learn are our main characteristics; our team is young, bright and dynamic, it has shown an outstanding ability to face the enormous challenge of launching new projects in very short periods according to the requirements of our clients, fulfilling them in time, costs and form ”, commented Jan Seumenicht.

PIRELLI AT THE FOREFRONT IN TECHNOLOGY AND COMMITMENT

Under the commitment to manufacture tires that exceed market expectations and in this way, support growth plans, Pirelli guarantees closeness and knowledge with its customers through its R&D located at its plant in Silao, Guanajuato.

According to Roni Viana, head of the R&D laboratory at Pirelli México, the proximity to the client and the production lines allow them to focus on the characteristics related to the performance of their high performance and ultra high performance tires, since by investing in research and development ensures that you are at the forefront of innovation and technology.

Pirelli currently has 5,800 patents, 150 external projects in materials, processes, software and electronics and more than 100 projects that are carried out in partnership with OEM Premium.

Its Research and Development Center is made up of 28 Mexican engineers from different specialties in the areas of development of materials, processes, products and experimental tests.

“It is a relatively young team, which is motivated to have an innovative spirit and commitment to the development of their work. Some of them have been at the Pirelli plant in Silao since before the production of tires began in 2012 and to incorporate them they were sent to develop training at our corporate center in Milan and at other plants of the group ”, he explained Roni Viana.

Currently, four engineers with more than 20 years of experience are incorporated, who provide training and support reinforcing the development of the technical skills of Mexican engineers.

In addition, Pirelli has a historical research collaboration in various areas with 28 universities and polytechnic institutes, notably the Università degli Studi di Milan, Bicocca and the Politecnico of Milan.

In Mexico, a successful project for the development of tools for simulation in Finite Elements stands out with the State Training Institute (IECA) in Guanajuato and the Tecnológico de Monterrey Campus León.

Pirelli is a company that is committed to increasing its participation in the electric vehicle (BEV) market, working in partnership with traditional European and United States assemblers and various startups. To do this, they have developed, through their R&D centers, a specific line of tires marked with the initials ELECT, which are designed to meet the requirements of this type of vehicle such as extension of the range of batteries, more weight of vehicles , greater torque, comfort and duration.

Another relevant point is the strategy to increase the use of sustainable materials, recycled or from renewable sources and the reduction of materials of fossil origin.

“Pirelli's constant commitment is to improve economic, social and environmental performance throughout the entire value chain, from the selection of suppliers to guaranteeing safety and health at work, from respect for the environment, to the sustainability of the new products is fundamental to our business model, which aims to create value for all its stakeholders ”, said Roni Viana.

BEIERSDORF MANUFACTURING, INNOVATING FOR LATIN AMERICA

Marcus Favaro, R&D Beiersdorf Manufacturing laboratory manager, explained that for the company it is valuable to have an R&D Center within its facilities to facilitate the development of new products, this proximity drives the creative spirit and sense of pride. Also, he considered that it is useful to solve technical problems in a faster and more efficient way.

This center was created seven years ago and is currently made up of engineers, most with university degrees in engineering such as Chemistry, Biotechnology, Biology and other related areas.

In this area, new formulas for cosmetic products and alternative packaging are being developed, in order to contribute to sustainability. Various claims and tests, fragrance development, and long-term innovation projects are also conducted.

Beiersdorf has an international research network, which is involved in more than 300 partnerships with universities, research centers and start-ups. These have led to countless innovations, one of which was the Nivea Black & White range, a range of deodorants that maintain the colors of the fabrics.

“This collaboration generally starts from a consumer vision or a special project need and there are many ways we approach our partners, whether through our confidential network of companies, institutions and scientists, supplier fairs and Incubation. Labs, that is, collaborations with other companies that are conducting research as well as suppliers of raw materials ”, he explained.

Yanel del Moral González, R&D Beiersdorf Manufacturing laboratory manager, announced that this R&D Center located in Silao, Guanajuato, is responsible for developing products for the categories of body care, sun care and deodorants for more than 100 countries in Latin America, Africa, the Middle East, Southeast Asia and Oceania. It is the second most important center for these categories and the number 1 in bars of soap in the world.